The importance of technical support – and knowing when to use it.

The importance of technical support – and knowing when to use it.

Every burner engineer knows the moment: you’re on site, everything’s wired in, but the burner just isn’t playing ball.

Whether you’re dealing with a smaller residential oil unit or a powerful commercial gas burner, a solid grasp of fault-finding is essential, but so is knowing when to pick up the phone and being sure of getting the technical support you need.

Riello’s UK technical helpline taking thousands of calls a year from heating engineers, installers and service technicians looking for support. We speak with Graham Barker, Sales & Service Director at Riello Burners in the UK, Carrier RLC EMEA says, our UK to find out more about the questions being asked by oil heating engineers.

They vary in complexity, but many follow familiar patterns, revealing interesting insights into the realities of burner commissioning and servicing, as well as the importance of good design, responsive support and clear documentation.

In both residential and commercial settings, the most common enquiry is refreshingly simple: “The burner’s not doing anything, what do I check?” Often, it’s an external enable signal holding things up, or a simple wiring or voltage issue. Riello’s control logic is designed with safety and clarity in mind, if something isn’t right, it will hold fire rather than proceed.

With Riello’s residential oil burners, another recurring theme is the fan motor running while the burner fails to progress. This usually points to a flame sensor or component issue. The good news? With some basic checks to resistance values, coil voltages and the sensor, the fault can often be quickly identified. These aren’t complex systems, but they’re smart, and they know when to stop and wait for the engineer to catch up.

Burner performance isn’t just about ignition; it’s about the fine balance of combustion. Another common question is: “What emissions should I expect?” For oil burners the typical CO2 level is in the 11.5-12.5% range and, with proper tuning, minimal smoke numbers.

These targets reflect Riello’s focus on efficient combustion and emissions control, helping engineers meet performance expectations and compliance requirements with confidence.

A particularly frustrating fault is the burner locking out one second after ignition. Engineers know it’s about the combustion triangle – fuel, air and spark – but Riello systems offer a level of clarity that helps you track the issue down. On Low NOx RDB BX models, even flame luminosity comes into play, with diffuser settings used to enhance flame detection in blue-flame conditions.

Closely related is the issue of continuous cycling with no lockout, a sign of communication breakdown between the flame sensor and the controller. Again, simple checks or adjustments to combustion settings usually solve the problem. In Riello’s Low NOx RDB BX models, fine- tuning of the diffuser settings can also make all the difference as the issue can be that the Low NOx ‘blue’ flame is present, but due to reduced luminosity the flame sensor cannot register the ‘running’ flame – it will detect the initial ignition which has a high luminosity, but when this quickly settles to the running flame the luminosity can be much lower which results in the flame sensor not ‘seeing’ the flame and attempting a new ignition sequence..

When it comes to oil burners, nozzle sizing is a question that never goes away. It depends on heat input, fuel type and pump pressure, and while the maths is straightforward, Riello’s documentation makes it easier to navigate. The aim is always balanced performance, and predictable control across stages of operation.

With the phase-out of certain older servomotors, engineers occasionally encounter wiring challenges when fitting new replacements. These conversions are fully supported with new diagrams and advice, and most issues can be traced back to one or two incorrectly assigned cables.

Finally, burner diagnostics remain a favourite topic. For burners using Siemens RMG or RMO controllers, the built-in ‘blink code’ system allows rapid diagnosis of lockout causes.

One push of the reset button puts the controller into diagnostic mode, and the LED pulses out the fault code, making it easier than ever to see what’s wrong and get it sorted.

What these enquiries show, above all, is that even the most capable engineers value backup.

Riello believes that technical excellence shouldn’t stop at the product. Riello’s burners are built for reliability, but when things don’t go to plan, the right support is important as Graham concludes: “Engineers are there to keep the heat on so, if a query arises, our technical team is there to guide, advise and support with a helpline that really delivers.”

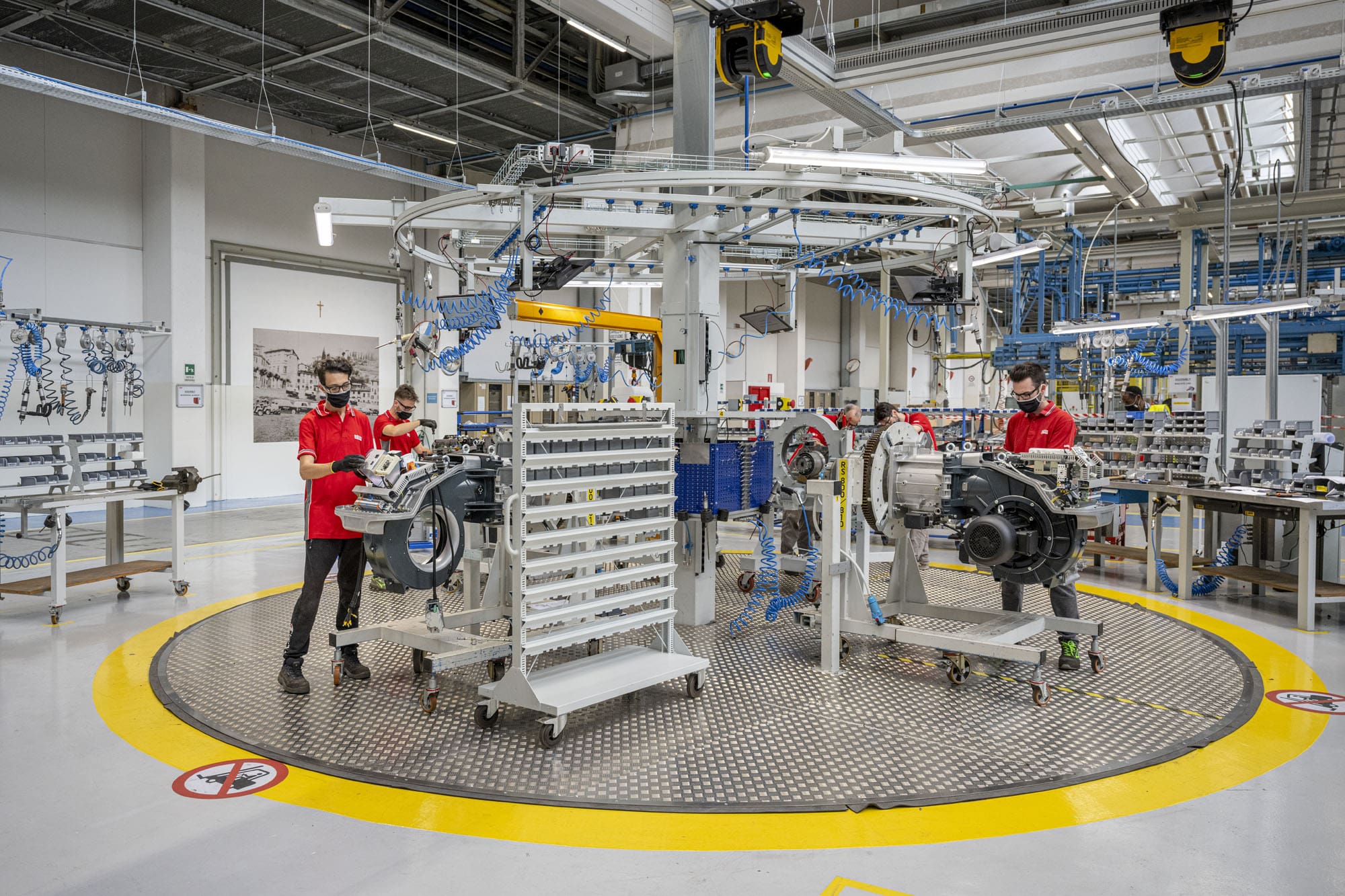

Images provided by Riello

© 2025 Created by Euromedia Associates Ltd